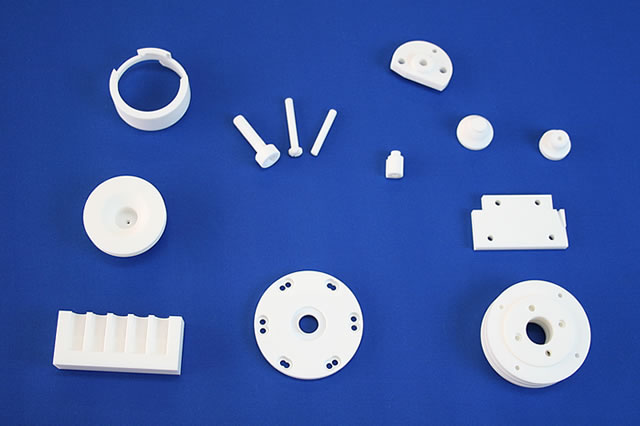

Machinable Ceramics

Precision, Quality, Machinability, and Time-Effectiveness

All Combined As One — Machinable Ceramic

Machinable Ceramic showed extraordinary machinability with precision in conventional machining. Not just diamond-based cutting tools are able to make various precision machining, but also general carbide tools. In the fast-changing market of inspection jigs and manufacturing of liquid crystals display and semiconductors, large variety and small quantity are always required. It has a shorter lead time from design to trial production as our customers demanded. The precision, quality, machinability, and short delivery time of machinable ceramic had made it widely used and welcomed around the global market.

Application

- Semiconductor Equipment parts

- Semiconductor Inspection Parts

- Leaser Equipment Parts

- Vacuum Equipment Parts

- Thin Film Deposition equipment Parts

- Liner Motor Parts

- Ultrasonic Generator

- Various Insulating parts

- Insulation parts for various analyzer

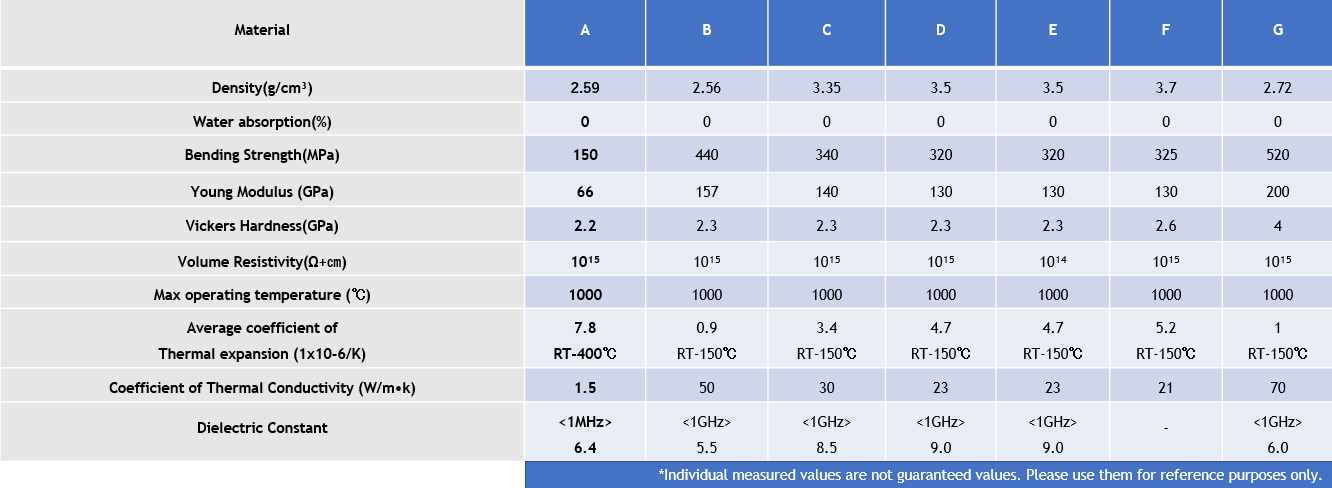

Machinable Ceramics characteristics table